About Us

Who We Are?

Green Cables® is Pakistan’s foremost electrical cable manufacturer, recognized for our unwavering commitment to quality and innovation. With a legacy of over a decade, we specialize in producing a comprehensive range of electrical cables and conductors.

Headquartered in Lahore, Pakistan, Green Cables® stands as a pioneer in solution based electric energy conservation. Our dedication to Green Energy has guided our journey, inspiring us to manufacture high-performance, low-smoke zero-halogen cables and wires.

How We Started?

Foundation of Green Cables 2008 2010

The inception of Green Cables is rooted in a compelling vision and resolute dream. Motivated by a fervent aspiration to position Pakistan’s electric wires and cables industry as a formidable player on the global stage, our CEO, Mirza Adnan Manzoor, embarked on a journey of unwavering determination to lay the foundation of our company. With a strategic vision to compete with renowned international brands in the high-tech electrical wires and cables sector.

- Established to fulfill the demand for specialized cable solutions.

- Driven by the ethos of Green Energy and a strategic response to market gaps.

- Ventured into the market of custom designed and niche specific cables for control, instrumentation, signal cables.

- Providing alternatives to specialized products from major global brands like General Cables, Belden, Draka etc.

Vision

Established to fulfill the demand for specialized cable solutions. Driven by a passion for quality and sustainability, Green Cables is dedicated to delivering safe, reliable and energy-efficient electrical solutions for a connected Pakistan

Mission

Delivering reliable and sustainable electrical solutions.

Green Cables envisions a Pakistan powered by sustainable, locally-produced electrical solutions, driving economic growth and fostering connectivity inn every corner of the nation

Our Clients

Our Valued Clients

Standards & Quality

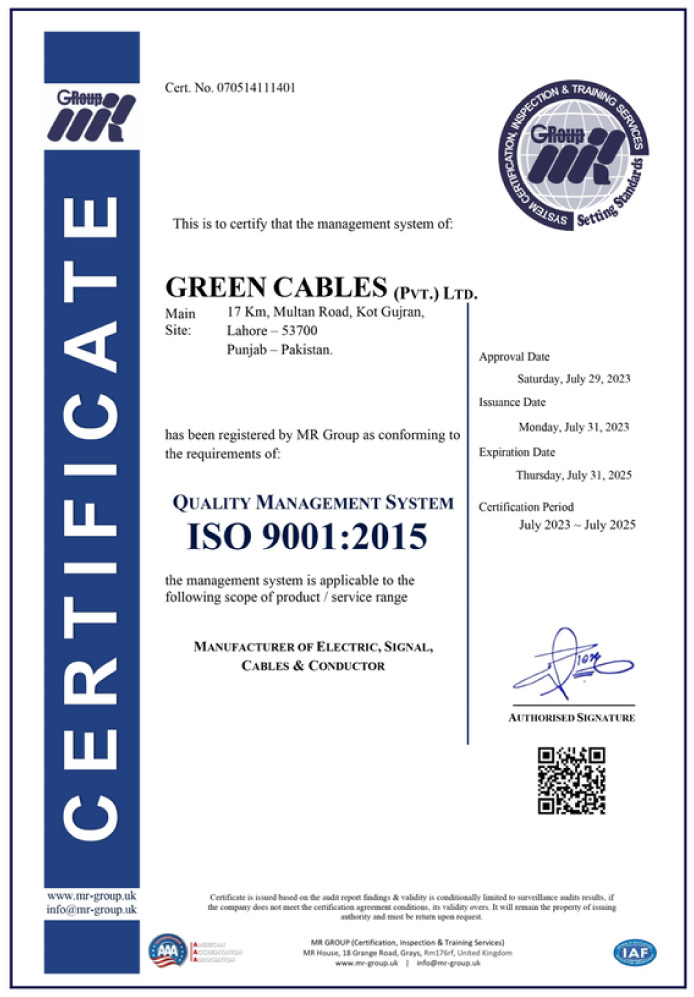

Green Cables’ adherence to ISO 9001, ISO 14001, ISO 45001, and CE standards demonstrates its unwavering

commitment to quality, environmental stewardship, workplace safety, and regulatory compliance.

ISO 9001:2015

Green Cables' ISO 9001:2015 certification reflects its unwavering commitment to quality management, operational excellence, and customer satisfaction.

ISO 14001:2015

Green Cables ' ISO 14001:2015 certification validates its comprehensive environmental management system, addressing and mitigating environmental impacts across its wire and cable production.

ISO 45001:2018

Green Cables' ISO 45001:2018 certification validates its proactive occupational health and safety management system, ensuring a safe and healthy work environment for its employees across all operations

CE Certified

Green Cables' CE marking signifies compliance with relevant EU directives, assuring customers that their wires and cables meet stringent safety, health, and environmental standards.

We manufacture our products across a broad range of standards

including national, intra-national and international standards

IEC Standards

International Electrotechnical Commission

BS EN

British Standards

DIN VDE

Deutsche Institut für Normung – Verband der Elektrotechnik

GB Standards

National Chinese Standard –

UL Standards

Underwriters Laboratories

CSA Standards

Canadian Standards Association

TIA/ANSI

Telecommunication Industries Association / TIA/ANSI ISO Standards International Organization for Standardization

American National Standards Institute

ISO Standards

International Organization for Standardization

Compliance, Quality, Safety

Standards established by national and international regulatory bodies are

designed to ensure the manufacturing of products that adhere to stringent safety and regulatory requirements, tailored to their specific applications and utilities across diverse markets.

Compliance with these standards ensures the production of high-quality products with validated performance, fostering unwavering trust in Green Cables among our valued customers.

Our commitment encompasses rigorous adherence to regulatory requirements, the utilization of premium-grade materials, and the engineering of safe products that achieve superior performance and cost-effectiveness.

Testing -Internal

A little glance into our internal testing protocols

Raw Materials Inspection / Testing

We conduct thorough visual inspections and precise dimensional checks on incoming materials like conductors, insulation, and jacketing to identify defects and ensure proper fit. Various tests, including conductivity, tensile strength, elongation, cold bend, and dielectric testing, confirm that materials meet our high standards for performance, flexibility, durability, and electrical resistance.

In-Process Quality Control

During extrusion, we use sophisticated monitoring systems to track temperature, pressure, and speed in real-time, ensuring consistent quality of insulation and jacketing. We also employ spark testing, a non-destructive method that applies high voltage to detect defects, ensuring the electrical integrity of the finished product.

Final Product Testing

Final testing includes high-voltage tests for insulation integrity, insulation resistance checks, and continuity tests for conductor reliability. Dimensional accuracy and sheath integrity are also verified to ensure compliance with international standards, guaranteeing high-quality, safe, and durable cables.